this has been a long time coming: finally we are making the first steps towards building our new home. we’re not complaining: the main reason why it took us so long was the fact that while we accept that we will certainly find we could not avoid every pitfall, we wanted to make sure we gave ourselves the best chance of building the house we really wanted.

we definitely did not set ourselves an easy target. our plan is to build a house that is as sustainable as possible by today’s standards. that means a low carbon footprint & low embodied energy, but mainly a very comfortable home with very low resource use – remember the house will be entirely off-grid.

this means we will have to consider not only our energy use, but also our water consumption and use of detergents in our waste. in terms of energy in particular we will rely heavily on the concrete slab performing one very important function: it needs to equalise the temperature in the house.

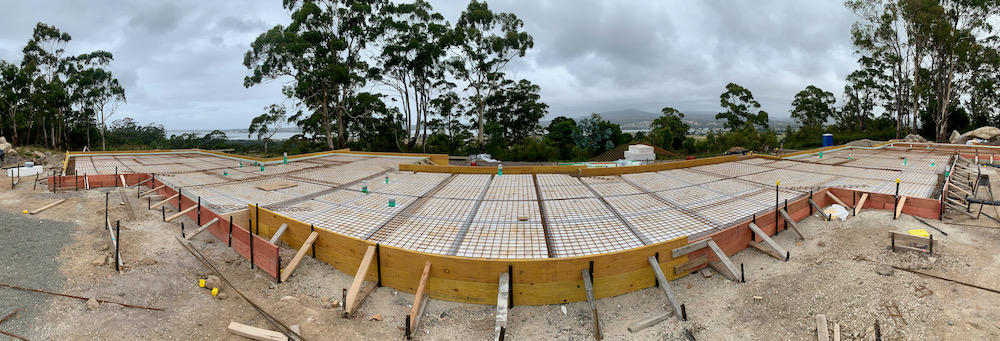

given the high standards we have set for ourselves, the picture above looks wrong. steel – and lots of it, plastic distance pieces, styrofoam blocks and closed-cell polystyrene insulation on the sides does not exude low environmental impact. and that is before the concrete is added to the equation (and the slab).

this is a difficult choice: on the one hand we agree there appears to be way too much non-natural material built into the foundation of our home. on the other hand these choices are driven by important long-term considerations that we believe will make out house energy efficient, environmentally sustainable and comfortable to live in in the long term.

to achieve this, as mentioned above, we need a dense foundation as a heat bank, and for that to function as expected the slab needs to be well insulated. this of course means horizontal heat loss, but importantly also to the sides, which i believe is where most energy is actually lost if the slab is not insulated.

then there is the concrete itself, which is unfortunately not really environmentally friendly: manufacturing of cement is said to be responsible for 5% of carbon dioxide emissions globally. it’s not great, we agree, but we didn’t find an alternative that would have met our requirements (even though there probably is such an alternative somewhere).

the guys also commented on the heavy gauge steel the engineer specified. we’re not really sure why we need a foundation that looks like planes could land on, but at least we can hope that it won’t budge.

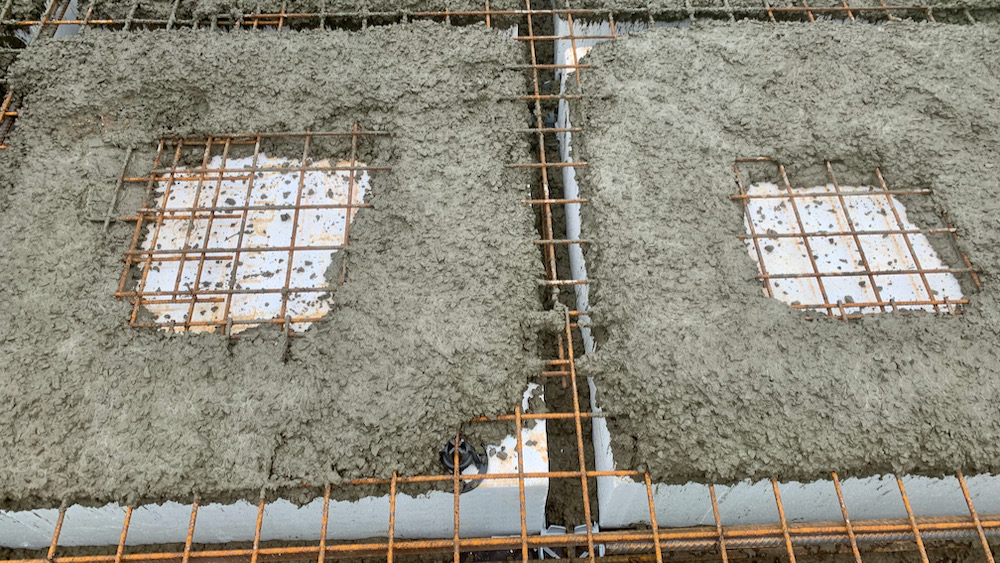

we know all the guys who helped pour the concrete, and almost all of them are mountain bikers. that’s probably a good preparation for this job: once the concrete is on the ground there is no time to waste, and the guys need to move quickly.

thankfully the wether was not too warm and we had some cloud cover, which slows the curing process. in the evening we even had a few drops of rain, which we are told helps ensure the slab cures slowly and hardens well.

in any case the slab will sit there now for a few weeks, until the guys return to construct the timber frame for the walls. once that is up, the roof will be next, and then it will get more exciting: that’s when the hempcrete walls will go up. we’re really looking forward to that.