stuff breaks. high loads, massive kinetic shocks, uv light and salt water will, given time, destroy nearly everything. and sometimes there is a know-on effect, so when one thing breaks it then transfers too much load onto other parts, which then fail as well. the spinaker pole appears to be a case in point: when one of the 3mm dyneema ropes holding that fails the load transfers onto the aluminium pole and that can’t withstand the force of the lite.

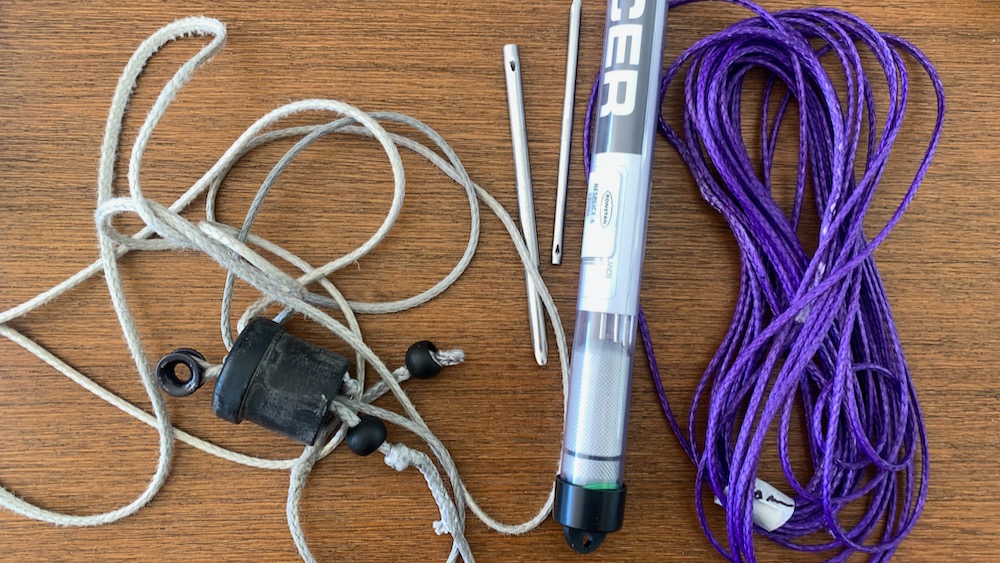

this is why it makes sense to replace the dyneema lines before the uv light weakens them beyond breaking point. and i finally had the time and managed to remove the plug from the tip of the spin pole. purple looks so much better than the bleached white but using a different colour also helps track what is new and what isn’t.

the whiskers are the dyneema lines running from the tip of the pole to the front of the hulls and put downward force on the pole when the kite is up. the plug also holds the tack line that pulls the tack (front lower corner) of the kite out when it is hoisted.

and this is how it all should look like. it will stretch a bit but i have made them adjustable so it will all be tensioned as it should be. so while on the subject of the kite, i did a bit more work to make nat’s job of getting it up and down as fast and easy as possible. hence i decided to replace the pivoting block with clam than sits about a meter above the tramp and is used to pull up and lock the kite.

the old one looked old and was bent, which generally does not help blocks run well. every little bit of resistance matters and usually once the bearings are worn or the roller is wedged the plastic starts to wear and the block drags even more.

this is the new one. cool black and spins as it should. no more resistance dragging this kite; i also marked the halyard where the kite is in the ‘fully up’ position so nat knows when she can lock it off.

and lastly i had to fix a broken off block from our 10:1 main sheet system. not sure why that took a bit of lateral load but it clearly did and it clearly didn’t enjoy that. the block then got wedged in the upper part of the main sheet system and made it hard to dump the sheet – not ideal on an f18. it was a quick fix, and i ordered two to replace both sides based on the premise that if one goes the second one is usually not far behind. it was a good call, too: the second one wasn’t broken but had already developed a small crack. that won’t slow us down now. i think we have now replaced almost all blocks – yay!