let me apologise at this point. i know the blog is meant to be about our travels and to this point it probably looks like the biography of a deranged mechanic. i assure you we will travel and there will be less to write about the car (i really hope that will be the case). but before we can actually start our trip through a country that is known to be pretty rough and go to see many remote places i want to make sure we got the best possible chance of getting around safely. and this is probably the last upgrade. probably.

i admit it: i left the least pleasant ‘upgrade’ for last. the land rover engineers obviously did a great job building that discovery around the v6 engine (fun fact: to perform more complex engine service tasks like work on the turbos the cabin is actually lifted off the car!) and as a result space under the hood is at a premium.

what little space was left has long been taken up by the second battery that has mainly been installed to power a fridge. from various posts on the land rover specific forums i knew there was just enough room left for a small compressor somewhere between the brake distributor, the gearbox ecu (one of them at least) and the glow plug relays. well, a few things had to be rearranged …

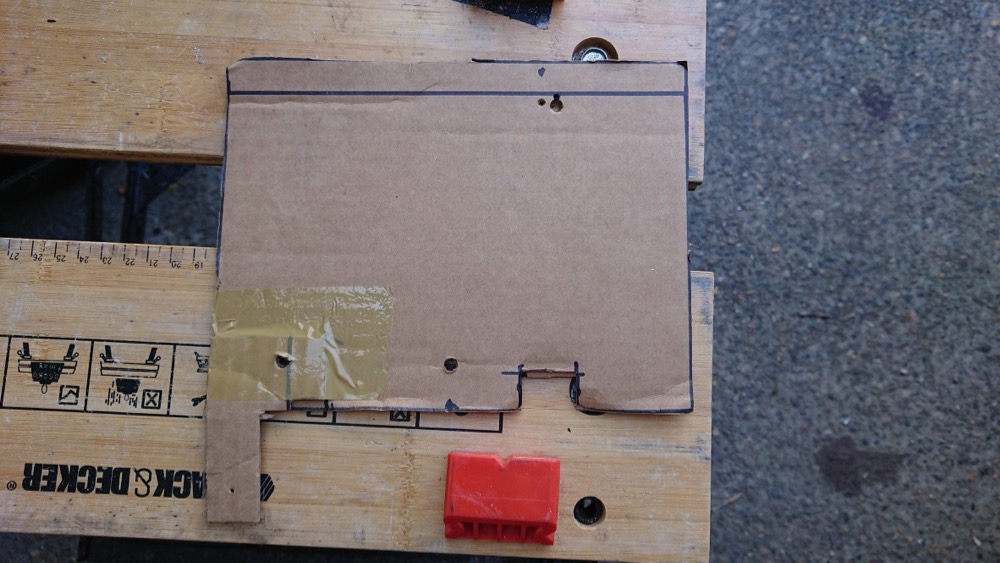

… and a carrier plate had to be fabricated. i created a cardboard sample first.

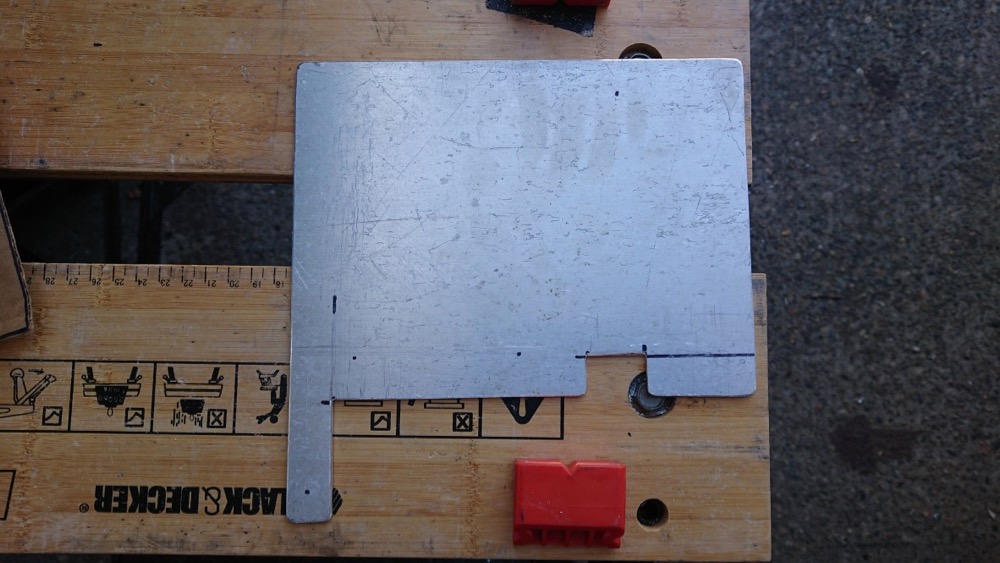

the ‘real thing’ made from 3mm aluminium. i wanted to make sure i got it right and there is absolutely no room to take precise measurements but my cardboard stunt double did a good job.

see the little compressor in there? with the air hose sticking out? not much wriggle room. i had to sort out a few details related to my ‘simplified’ loom. looks like i oversimplified it and as a result it did not work so well (read: not at all). however, after i worked my way through all the connections with a multimeter i worked out i needed another 12v positive connection.

it’s all good now & working as designed (obviously not by the land rover engineers).

btw for those of you who are wondering why i went to all this trouble to install an air compressor in the car: when driving across certain types of road (soft, sandy, corrugated, …) the air pressure in the tyres must be reduced to provide more traction and / or help the suspension. that’s the easy bit (we got a tool for that). once back on firmer ground the tyres must then be re-inflated and there is not always a handy service station nearby – hence the on-board air compressor.

it’s all about being self-sufficient.

although i suspect our friend ben would suggest we can use the air compressor to cool ourselves when stranded in the desert.