the trouble with building with hemp is that it is not immediately visible if the work has been done more or possibly less well. that is only revealed when the formwork is removed. then everyone can see if the brew (we learnt that is what the mix of hemp, lime, sand, binder & water is called) has been correct or not. that typically happens a day or two later, and by that time it becomes difficult to re-calibrate everyone’s wrists.

and just to be clear: this isn’t a matter of using one recipe over and over again. warmer weather may require more water to achieve the same consistency, while mixing on or after a rainy day will need an adjustment for the excess moisture in the hemp and the sand. that is assuming the mix is done correctly to begin with: we’re not sure what happened on the wall above, but the darker layer is missing a fair bit of lime while the layer above it contains significantly more moisture than it should.

there is a bit going on here. everything has to be pre-measured and prepared; once the mixer is going and the water is in there is not time to loose. all materials need to go in in quick succession, otherwise the hemp soaks up all the water and the brew will not work as required.

there are other pitfalls: restarting the process after a weekend can be tricky, because the previous wall would have cured to a point that the new layers may not stick to it as well as they should. the pros recommended sprinkling a bit of binder on the old layers to aid the adhesion – we just went a bit overboard with the sprinkling.

i’m happy to look at the white streak as adding ‘colour’, but kris isn’t happy with it, especially since this happened in a spot that we would have liked to leave raw. i think we still can, right?

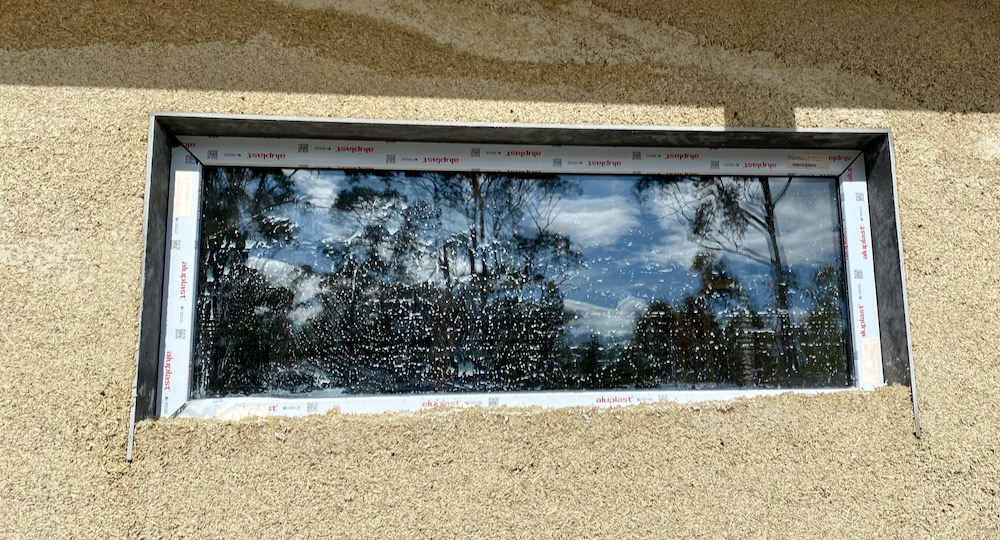

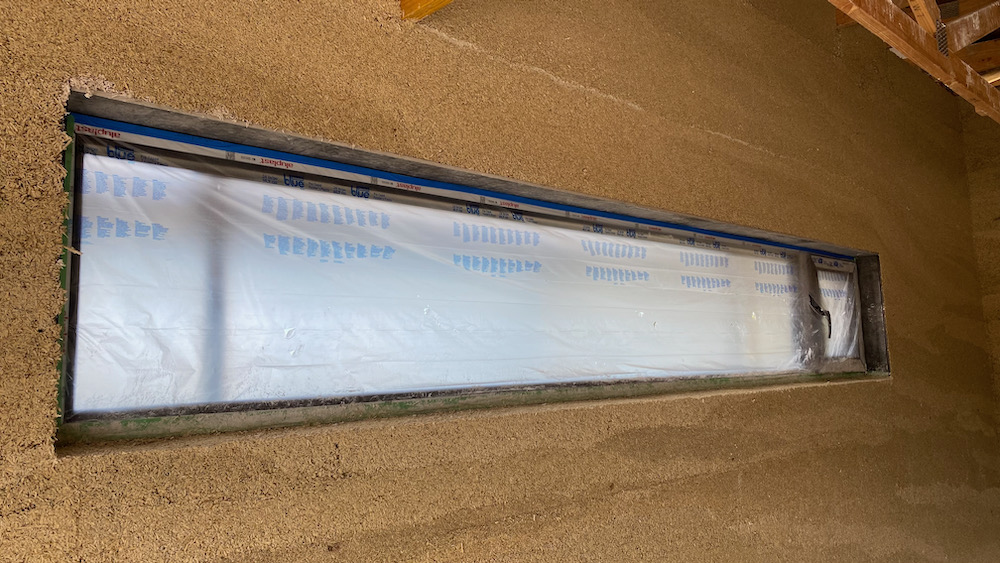

this ‘miss’ isn’t so much a hemp construction thing as a design issue. issue may be the wrong word, it is more a choice we would not repeat if we had our time again. the hemp walls under and between the windows would probably work better if there was more of it. sure, that would mean smaller windows, and the view is definitely spectacular. but next time we would raise the window sill to, say, 400 mm, and make the column between the windows larger so the hemp is actually visible and not squeezed in between two cement sheets.

we would definitely like to keep a few walls exposed. that means having to close the holes the formwork screws left. kris learnt a new way of doing this quickly and without making a mess. there are a few holes to fill, it will keep us busy.

so there are a few spots that could have worked better. we also think that our tamping is a bit hard in general. again that isn’t a problem as such , we’ll just end up using more material than technically required.

but overall we are happy with the way things look. we can’t wait for all walls to be completed. it won’t be long now.